Functional knowledge of active feeder

2020-07-03(1421)Views

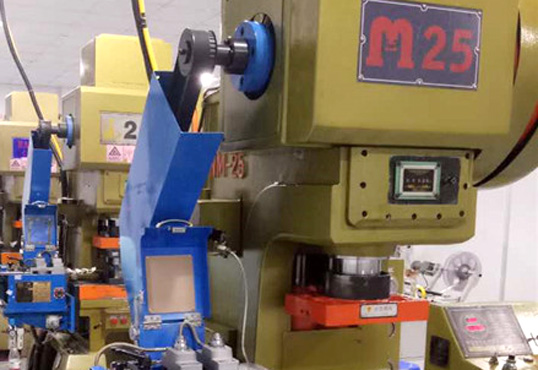

The active feeder is used as a machine to transmit data. Occupation is very wide, and it is one of the necessary equipment in light industry and heavy industry.

The principle is also a machine that the machine generates motion by means of electric power and applies the force of the motion to the data to carry out the required transportation of the data. In the modern feeder, the power technology has undergone a revolutionary change. For example, some emerging technologies such as high-pressure air, ultrasound, etc. power transmission began to be used in the feeder.

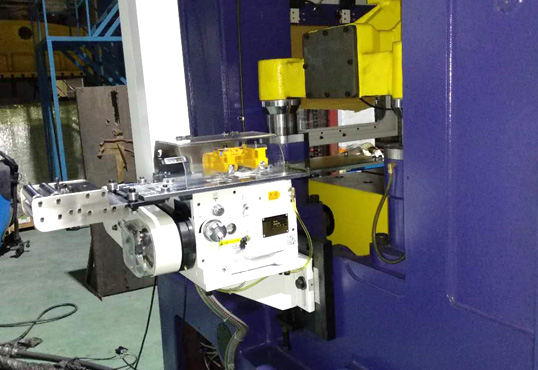

The actual use of the active feeder is marked: the selection of a reasonable AC servo system can satisfy the requirements of the control system for fast response, high speed accuracy, and strong robustness. The actual use position control accuracy is up to about ±0.1mm and the cumulative error can be avoided. The control system can be used in the production of high-precision opening series cold-formed steel products, especially products similar to shelf columns, that is, cold-formed online pre-punching for cold-formed steel vertical and side surfaces with high-precision hole position requirements Production line.

During the use of the machine, the internal parts of the machine will cause wear and other problems. For the performance of the machine and the safety of the machine, the maintenance of the feeder should pay special attention to the following six points.

1. Apply gear butter to the gear part of the roller and make up for the replacement gear oil.

2. Whether there is dirt between the rollers and whether there is foreign matter between the gears.

3. Whether the feeding roller has excellent parallelism.

4. Whether the screws and nuts combined between the feeder mechanisms are loose.

5. Whether the switch on the operation panel and the display are abnormal.

6. Are there any abnormal phenomena such as damage and deformation in each part?

Precautions for using active feeder:

1. Ensure the best mold gap The mold gap refers to the sum of the gap between the punch and the lower die. It is related to the plate thickness, material and stamping process. Choosing the appropriate mold gap can ensure excellent punching quality. , To reduce burrs and sinking, insist on flat sheet, useful to prevent tape, extend the life of the mold. The active feeder can determine whether the mold gap is appropriate by checking the stamping waste. If the gap is too large, the waste will have rough and rugged cracking surfaces and smaller shiny surfaces. The larger the gap, the greater the point of view formed by the cracked surface and the bright surface. When punching, it will form curling and cracking, and even a thin edge protrusion will appear. On the contrary, if the gap is too small, the scrap will have a small-view cracking surface and a large shiny surface. When grooving, nibbling, shearing and other partial stamping, the lateral force will deflect the punch to form a single-sided gap that is too small. Sometimes the edge deviation is too large, which may scratch the lower die and constitute rapid wear of the upper and lower dies. When the die is stamped with the optimal gap, the cracked surface and the shiny surface of the scrap have the same viewpoint and overlap each other, so that the punching force is minimized and the burr of the punching hole is very small.

2. The proper sharpening can be useful to extend the service life of the mold. If the workpiece has excessive burrs or abnormal noise occurs during stamping, the mold may be passivated. The CNC feeder checks the punch and the lower die. When the blade wear occurs It is necessary to sharpen the arc with a radius of about 0.10mm. Practice indicates that a small amount of sharpening is often performed instead of waiting until it is not necessary to sharpen. Not only does it adhere to outstanding workpiece quality, but also reduces the punching force, and It can extend the die life by more than double.

Recommended News

-

One-feed one-pull punch feeder

In addition to the conventional automatic feeding method of ...

-

Large deflection material rack with deflection NC servo feeder

The large deflection data rack with deflection NC servo feed...

-

The principle of the clip feeder

The production of stamping is moving towards high speed and ...

-

Functional knowledge of active feeder

The active feeder is used as a machine to transmit data. Occ...

Contact Us

Service Hotline+86 13580817073

—— WeChat communication

+86 13580817073

+86 13580817073